The World Record Powertrain

How efficiently can chemical energy, stored in pure hydrogen gas, be converted into mechanical energy at the wheel? This is a complex question with a complex answer. Our answer to this has evolved over the year, from our original DC/DC converter for the Shell Eco-Marathon to the simplified world-record solution. This article is meant to illuminate some of the general design decisions made without going too far in-depth. If you’re looking for additional clarification or information, please contact us using the form on our website!

Bubble wrap for last minute water shielding!

Numerical Overview

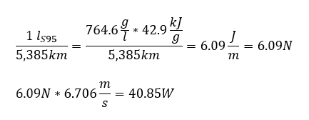

The team set out over the summer of 2018 to beat the previous world record held by PAC CAR 2. We started by analyzing the previous record to give a rough idea of how our car would have to perform. The previous record was set at 5,385 km/l, or about 12,600 MPG. Using the constants in the 2018 Shell Eco-Marathon Rules, this means that the PAC CAR dissipated roughly 6.1 N. At our car's design speed of 15 mph, the total power consumption of the car was 40.8 W of chemical energy stored in hydrogen.

However, given a nominal fuel cell system efficiency of 58%, the average electrical energy produced by the fuel cell and consumed by the motor should be lower than 23.6 W. Given an estimated motor and drivetrain efficiency of 87%, then the mechanical power dissipation of the car should be less than 20.6 W.

This average electrical power figure of ~23 W was used extensively in the design and optimization of the fuel cell. It gave a nominal power level to optimize around, and helped us make quick judgments of how significant each power loss was. For example, the Teensy 3.2, our usual micro-controller of choice, draws about 300 mW when powered from 5 V. If we had used the Teensy, we would lose 1.3% efficiency just powering a microcontroller!

Load Levelling

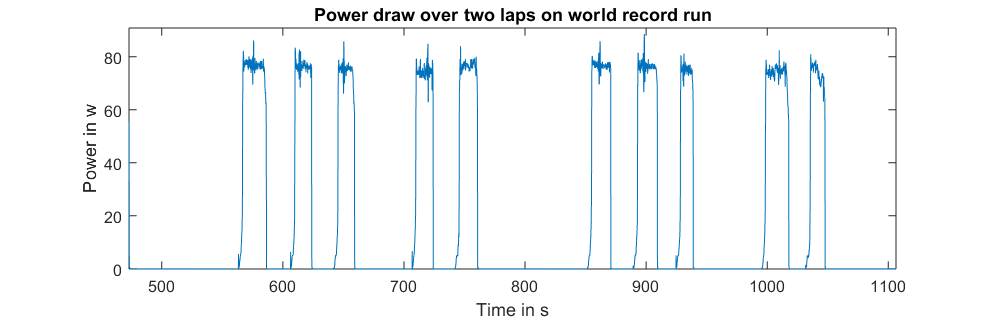

Once the average power level has been calculated, we must design and size the fuel cell system to be maximally efficient at this power level. However, while the average motor load over the entire race is 23 W, our choice of motor was most efficient at a much higher power, around 80W. Over the course of the race, the driver uses the motor in an on/off strategy to maintain speed. It became evident to the team that passing this pulsed load directly to the fuel cell load is not optimal.

The team considered three system architectures which could maintain high efficiency at these pulsed power levels.

No load levelling: Motor controller directly connected to fuel cell output with no intermediate energy storage

Active load levelling: Custom DC/DC converter between fuel cell and super capacitor bank for full control of fuel cell

Passive load levelling: Large supercapacitor bank connected in parallel to the fuel cell output

The first approach requires that the fuel cell directly supplies the full motor power. Thus the fuel cell itself must be optimized around the motor power of 80 W rather than the nominal 23 W. However, it also must be “optimized” for the 0 W case, requiring a low gas leakage and quiescent current draw. This architecture was discarded since the fuel cell performs less efficiently under a highly dynamic load than a constant load. Additionally, the larger stack required to produce 80 W efficiently has higher leakage and auxiliary losses than a stack sized for the nominal 23 W.

The second method, using a DC/DC converter to actively control power, was implemented on our car Gemini for the 2018 Shell Eco-Marathon. Our team built a entirely software-controlled boost converter to step the fuel cell voltage up to a higher supercapacitor and motor voltage. Since the converter was completely configurable, the converter drew a constant power from the fuel cell and into a supercapacitor bank, maximizing fuel cell efficiency. This entirely decoupled the fuel cell from the motor, and was the theoretically cleanest option. We implemented this architecture for the 2018 Eco-Marathon, however our implementation of the converter only reached 96% efficiency. Additionally, the converter and the associated software and hardware added significant complexity and unreliability.

The supercapacitor bank used, made of seven 1200F supercapacitors in series. Lipo with similar energy capacity for scale!

Thus, for the world record attempt, the team decided to use passive load levelling. A large supercapacitor bank was connected in parallel to the fuel cell and motor controller. The fuel cell would constantly trickle power into the supercapacitors, and the motor would discharge it in high-power bursts. The supercapacitors were sized large enough to keep the voltage and power draw from the fuel cell roughly constant over a lap. While this method suffers from a mass penalty due to the weight of the supercapacitors (~2kg), the simplicity of the passive solution is very attractive. We calculated that the losses from the dynamics of the fuel cell were smaller than the losses from DC/DC converter, showing that the passive solution was simpler and more efficient.

Energy flow for the world record powertrain

The supercapacitors operate above 99% efficiency, with most of their losses coming from their internal resistance. The supercapacitor bank was measured to only have ~10 mOhm of internal resistance during the race, which is much lower than a similar lithium-ion solution.

Fuel Cell

Now that the load to the fuel cell can be assumed to be mostly constant, we can optimize the fuel cell precisely for this load. Our team lacked the resources to build our own custom fuel cell, and thus relied on commercially available models. Sizing the fuel cell correctly is very important, as the practical efficiency of the stack is highest in only a narrow power range.

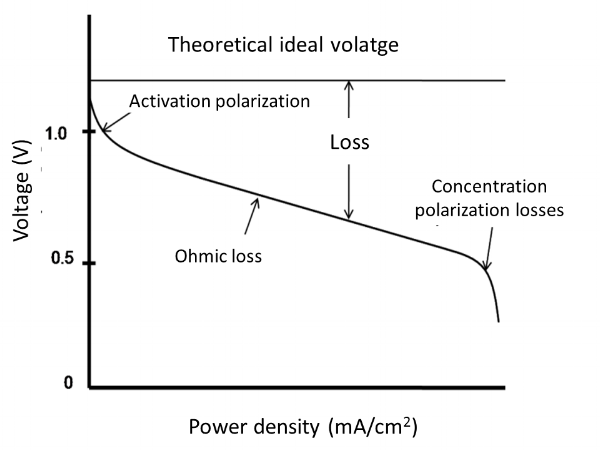

Theoretically, a PEM fuel cell is most efficient at an extremely low fraction of it’s designed power level. At very low power levels, the voltage produced by the cell is closest to the 1.229 V potential of a perfectly reversible reaction. As the current density of the cell increases, the ohmic and activation losses of the cell increase steadily, and the efficiency drops.

However, leakage of hydrogen through the membrane of the fuel cell is significant. This means that the fuel cell stack always consumes some hydrogen as the cell leaks. This hurts very low power efficiency since the leakage flow is significant compared to the flow used to generate power. This leakage effect scales with the stack size, and thus a larger fuel cell would have higher leakage. A compromise is required to find the most efficient fuel cell.

We found that most fuel cells are most efficient at ~20% of their rated maximum power. Thus, our team selected the Horizon 100 W stack to power our car for the world record. The Horizon stack is very easy to use, and is perfectly suited to our application.

However, because the Horizon stack is self-humidified, we had no way to directly control the humidity inside the cell. Water in the cell is critical to maintain good conduction across the membrane, and if the cell is too dry, ohmic losses increase. The team noticed this effect as the voltage produced by the cell dropped significantly below normal.

This problem of maintaining humidity became the biggest challenge of the entire record attempt. We did most of our fuel cell testing inside our lab around 23° C, however our record attempts took place in 35° C weather, and the back of the car reached 45° C after being left in direct sunlight. After a few of our record attempts, the stack reached 60° C internal temperature. We hypothesize that the high temperature caused increased evaporation in the stack, drying out the cells.

We spent a significant amount of time optimizing the short-circuiting and purging behavior of the fuel cell controller. We relied on frequent short-circuiting to increase the speed of the reaction and maintain humidity. However, short-circuiting the stack is inefficient and wastes hydrogen.

The humidity problem was so significant that the final record attempt took place on an overcast day at 9 AM, which helped keep temperature low and the fuel cell adequately wet.

Motor

A high efficiency motor is critical to the overall performance of the car. The motor must be light, robust, and in our case, reconfigurable to a range of input voltages. Few motor manufacturers list the theoretical efficiency of their motors, and even fewer have measured dyno results of these motors. Unfortunately, most of the resources available and vendors focus on optimizing other aspects of the motors, such as power density or cost. We struggled finding helpful resources that focused on efficiency. Our team eventually decided on using Koford motors to power the car. Not only were their datasheets very helpful, but their motors were highly efficient with dyno results to back them up.

Our team decided to use the Koford 60LH175A motor. The motor has a peak efficiency of ~92%, and is well sized to our car. The team built an inertial dynamometer to measure the efficiency ourselves. Unfortunately, in the results below, the motor controller was incorrectly programmed causing a significant decrease in low-speed efficiency. The real efficiency curves should be flatter, and the high speed results are more representative. These efficiency results are measured after the chain transmission, which we estimate reduces peak efficiency by 3-4%.

We used a chain transmission to transfer power from the motor shaft to the rear wheel. For the world record, the team used a #25 chain, with the motor driving a 14t sprocket, and a 120t sprocket driving a freewheel on the rear wheel. As the motor and controller are most efficient when at 100% duty cycle near the top of its speed range, the chain transmission allowed us to easily change gear ratios to let the motor operate at peak efficiency.

The team considered using a direct-drive hub motor, which can theoretically be more efficient than a motor using a transmission. However, most hub motors the team considered are designed for low cost electric bikes and are poorly documented and heavy.

The motor controller used very simple block commutation using the hall sensors. We attempted to use a blended hall and back-EMF commutation approach which would lead to more accurate timing, however our implementation was unable to match the performance of the classic hall commutation.

To control the motor, the driver was given just a button, rather than a throttle potentiometer. The vehicle was programmed to shut off most of its electrical systems when the motor wasn’t running to save power. This button performed a wake-up sequence, and throttled the motor at a constant current. Removing the driver’s throttle control improved consistency and performance, as the motor was always run near its optimal point.

Track Elevation

Selecting a good track for the record attempt was extremely important. A flat track allows designing the powertrain to much tighter margins than with a hilly track. The track must be smooth, flat, and with a minimum of sharp corners. Optimizing the car for a hilly track not only requires designing the car to operate at peak efficiency over multiple points (flat, uphill, downhill), but driver strategy and speed regulation is crucial to optimize efficiency. With a flat track these can be mostly ignored.

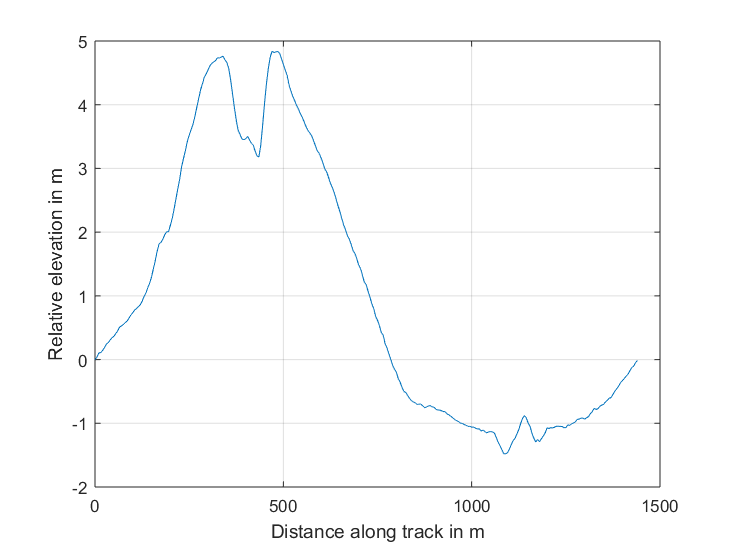

For example, we estimate that the efficiency scores from the 2018 Eco-Marathon Americas would be ~1.6x higher if the event were held on a flat track. The elevation change at the Sonoma Raceway was very significant; most cars had to be overpowered to climb the hills, and couldn’t regulate their speed going downhill. Unfortunately the track was poorly chosen for a supermileage competition. The team measured the Sonoma Raceway track very accurately using an RTK GPS to generate the following elevation profile.

Sonoma Raceway distance/elevation

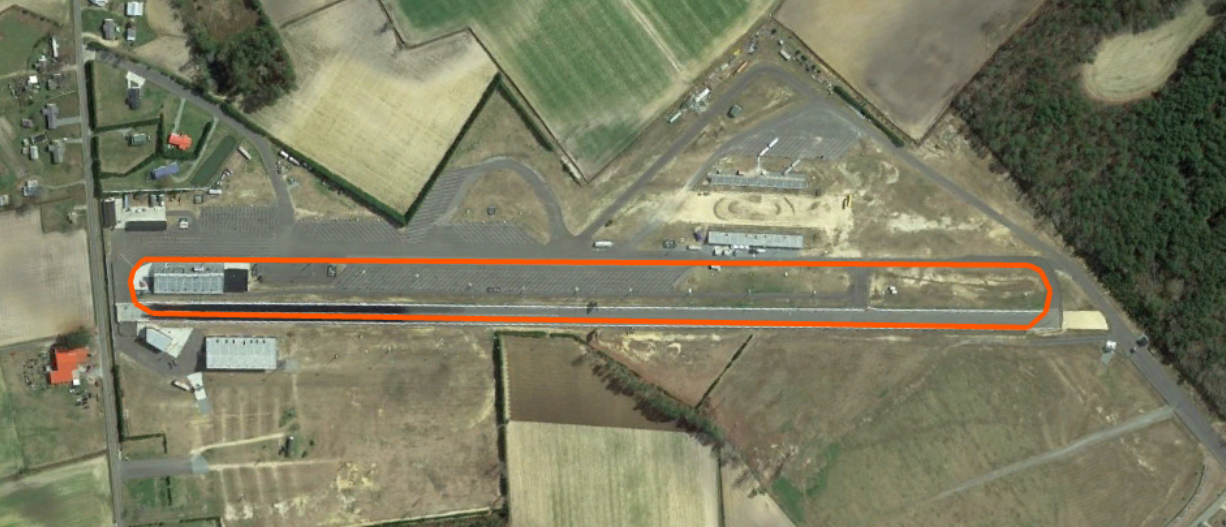

For our attempt, we knew that selecting a good track was critical to the performance of the car. The world record was attempted at Galot Motorsports, a very flat dragstrip with near our campus. Compared to the Eco-Marathon track, the Galot track was flat enough that the car could be optimized much further. Based on the elevation graph below, the steepest sustained slope is ~1.2m vertical/400m horizontal. To climb this hill at race speed, the car consumed only an additional 13 W of power. This still resulted in more frequent motor use going uphill than downhill, but this track was our best option.